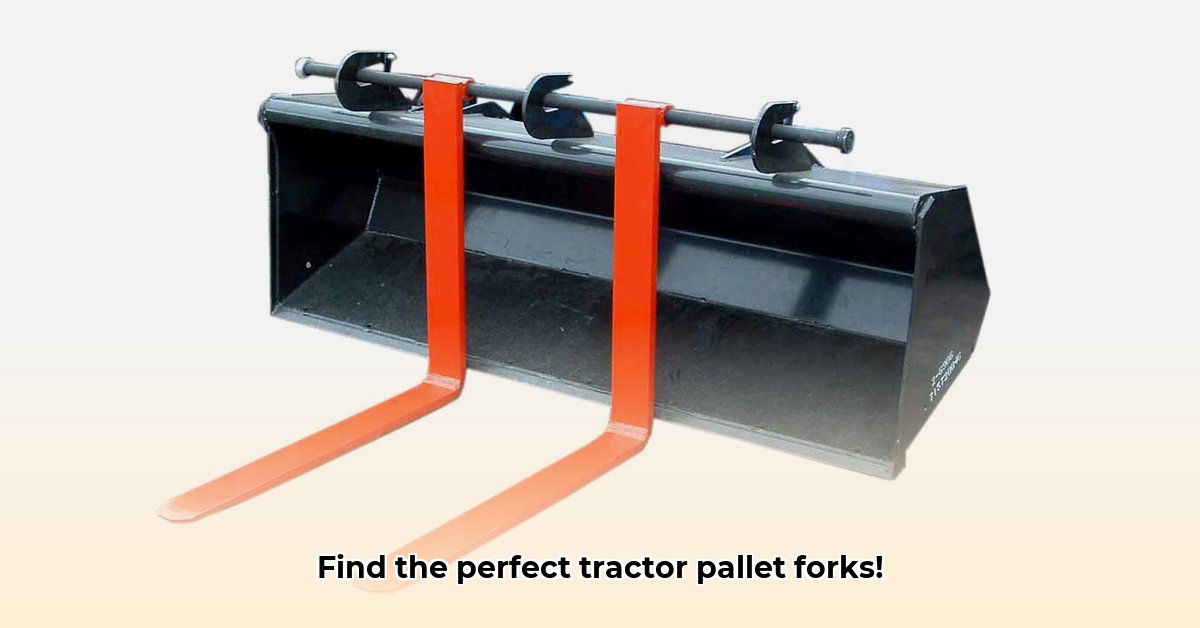

Choosing the right pallet forks for your tractor's quick-attach system is crucial for efficient and safe farm operations. This comprehensive guide will help you navigate the selection process, ensuring you choose forks that meet your specific needs and budget. For even greater lifting capacity, consider fork extensions.

Understanding Pallet Forks and Quick-Attach Systems

Pallet forks are essential agricultural implements used for lifting and moving palletized materials. They significantly enhance efficiency in various farm tasks, from handling hay bales to moving supplies. Quick-attach systems allow for rapid and easy swapping of attachments, significantly improving workflow.

Key Factors Influencing Pallet Fork Selection

Several critical factors influence the selection of appropriate pallet forks. Let's delve into each:

Capacity: Matching Forks to Your Lifting Needs

The weight capacity of your pallet forks must be compatible with your tractor's lifting capabilities and the heaviest load you anticipate moving. Underestimating capacity can lead to dangerous overloading, while overestimating leads to unnecessary expense. A safe margin is always recommended. How much weight do you regularly need to move? This fundamental question shapes your fork selection.

Materials: Durability and Cost Considerations

The material used directly impacts durability and cost. Hardox 450 steel, a high-strength alloy, offers superior wear resistance and longevity. However, it commands a higher price. Standard steel is a more budget-friendly alternative, suitable for lighter loads and less frequent use. What is your budget, and how frequently will you use these forks?

Attachment Systems: Ensuring Compatibility

Most pallet forks utilize universal skid steer quick-attach systems for easy interchange. However, variations exist between brands and tractor models. Always verify compatibility before purchase to avoid costly mistakes and potential safety hazards. Does your tractor use a standard system? Do you need versatility for changing implements?

Construction and Quality: Inspecting for Strength

Robust construction is paramount. Strong welds, thick steel gauge, and reinforced tines contribute to durability. Inspect welds for imperfections and ensure the overall build is sturdy. Choosing a reputable manufacturer is recommended. What level of durability do your tasks demand?

Safety Features: Prioritizing Safe Operation

Safety should be paramount. Always adhere to the manufacturer's weight limits. Regular inspections for cracks, bends, or worn parts are essential. Features like multiple safety chains further enhance safety protocols. Do your procedures prioritize safety? Appropriate safety features are a necessity.

Pricing: Balancing Cost and Value

Prices vary widely based on capacity, material, and manufacturer. While a lower initial cost may be tempting, consider the long-term value. Heavy-duty forks, while more expensive initially, often provide superior longevity and reduce the likelihood of costly repairs or replacements. What's your initial budget and your long-term perspective on maintenance costs?

Comparing Pallet Fork Options: A Practical Overview

The table below summarizes key differences between heavy-duty and standard-duty pallet forks:

| Feature | Heavy-Duty Forks | Standard-Duty Forks |

|---|---|---|

| Lifting Capacity (lbs) | 1200+ | 800-1000 |

| Material | Hardox 450, high-strength steel | Standard steel |

| Attachment System | Universal Skid Steer Quick Attach | Universal Skid Steer Quick Attach (verify compatibility) |

| Construction | Robust welding, thicker steel | Less robust welding, thinner steel |

| Safety Features | Multiple safety chains, reinforced tines | Fewer safety features |

| Price Range ($) | Higher | Lower |

Making Informed Decisions: A Step-by-Step Guide

- Assess your needs: Determine the weight capacity required for your tasks.

- Research manufacturers: Compare specifications, reviews, and warranties.

- Verify compatibility: Ensure compatibility with your tractor's quick-attach system.

- Obtain quotes: Compare pricing from multiple suppliers.

- Evaluate value: Consider the long-term cost of ownership, including maintenance.

- Prioritize safety: Always adhere to weight limits and perform regular inspections.

By carefully considering these factors and following this step-by-step approach, you can confidently select the ideal pallet forks for your tractor, optimizing efficiency and safety for years to come.